Considerable reduction in tact time and process working time

Looking to reduce chuck and de-chuck times?

1. Thanks to our proprietary high-speed response technology, Matsusada Precision's E-chuck power supplies apply voltage instantly. This ensures fast, smooth chucking with no time delay.

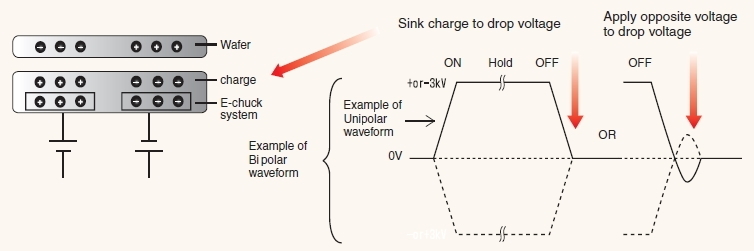

2. When de-chucking, our E-chuck power supplies not only turn off the high voltage but also actively discharge residual voltage on the electrostatic chuck, wafer, or glass substrate.

* This rapid and smooth chucking and de-chucking (releasing) significantly contributes to reducing the overall process time.

Long life and highly reliable design

Frustrated by downtime and maintenance caused by equipment failure?

- Our ECA series and EJC series utilize solid-state switching for polarity inversion instead of electromechanical relays. This design eliminates issues related to contact wear, ensuring long-term, failure-free operation.

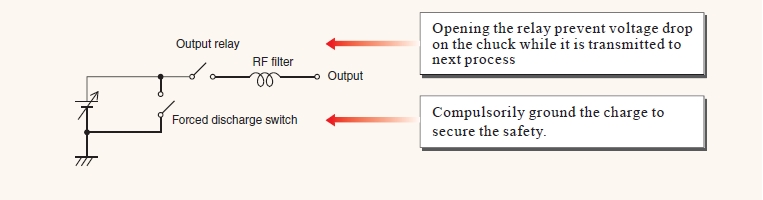

- RF filter, which is optionally available, protects the power supply from RF noise which can cause a failure or malfunction.

Unique and useful functions for E-chuck application

Matsusada Precision's E-chuck power supplies are designed with various functions, such as two-channel outputs for bipolar E-chucks, high-voltage output with user-defined waveforms, reversible polarity, forced grounding, and an isolation relay to disconnect the E-chuck from the power supply. Our E-chuck power supplies have all the functions required for E-chuck applications. This allows for control logic tailored to the user's specific requirements.

>>Click here to see a list of high-voltage power supplies for electrostatic chucks.

Related Technical Articles

Recommended products

Matsusada Precision high voltage power supplies are the best solution for semiconductor electrostatic chuck.